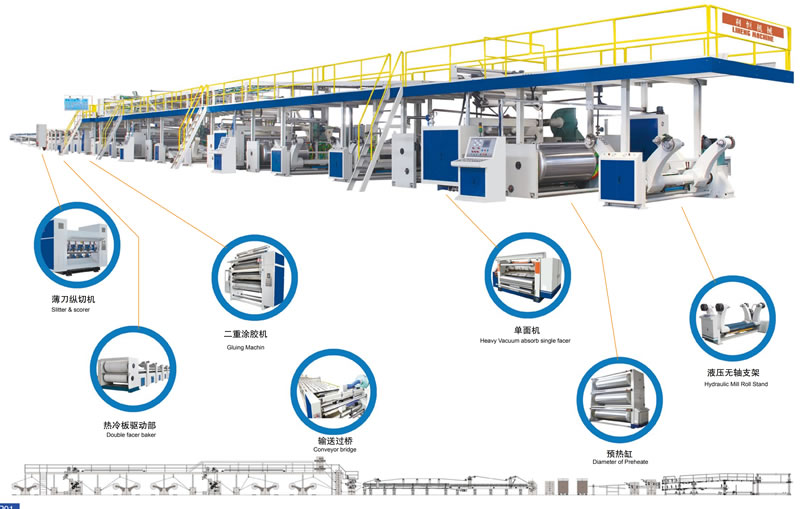

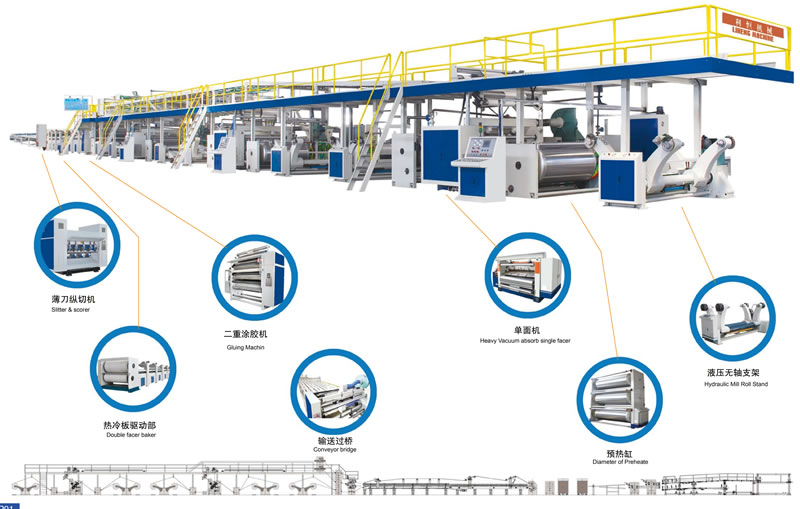

Three-layer five-layer seven-layer corrugated paperboard production line

| Mobile: | 0086-13653277171 |

|---|---|

| Tel: | 0086-317-7891877 |

| Fax: | 0086-317-7894000 |

| Email: | cartonboxmachinery@vip.163.com |

| Online More Information | |

| Share: |

|

Overview

-

五层瓦楞纸板生产线适合大批量自动化生产。生产出的纸板符合国家标准,生产效率高,纸板质量好,采取集中控制,操作简便,维修方便,安全可靠,大大降低了工人劳动强度。

产品介绍

Three-layer five-lay er seven-layer corrugated paperboard production line

五层瓦楞纸板生产线

用途与特点:

五层瓦楞纸板生产线适合大批量自动化生产。生产出的纸板符合国家标准,生产效率高,纸板质量好,采取集中控制,操作简便,维修方便,安全可靠,大大降低了工人劳动强度。该生产线采用目前国际新节能方式,用高温导热油给整机提供热源,比其他加热方式节约能源40%以上,大大降低了能耗,有效的压缩了生产成本,是当今经济型的理想产品,适合大中型纸箱厂使用。

一、整机总长度40-70米。

二、整机总动力约100-200kw。

三、有轴支架、无轴支架两种,供客户选择。

四、瓦裱机:瓦楞辊直径280mm-406mm,采用电磁调速电机。

五、二次涂胶机:调整方便,涂胶均匀。

六、烘干机:总长度7.8米,由9-18块加热板组成。

七、定型部分:由若干对成型轴组成,总长度约3.8-5米。

八、纵、横切机:根据用户要求可选装超薄刀机和普通刀机两种,自动化程度高,操作简便。

Use and Characteristics:

This production line is available in large amount automatic production, which can produce corrugated paperboard correspond to national standard with

high quality, and adopted concentrated control, operarated and repaired easily, safely, reliable, reducing manpower, This production line adopts international

energy saveing technology with oil heating, which can saveing 40 percents energy than steam heating, So this can reduce costs effectively. It's an economical

production in big, middle paperboard commpany.

1. Total Length: 40-70m

2. Total Power: 100-200kw

3. Two kind of frame with shaft and frame without shaft, provide the customer with the choice.

4. Corrugated paperboard marching: diameter of corrugated rouer: 280-406mm, electric adjust speed moter used.

5. Double cylinder gum mounting marchine: On the adoption, inside two layers draw the gun, dascend to carry the paper lead the paper roller.

6. Oven: total length 7.8m, combined with 9-18 heating flocks.

7. Setting Part: total length 3.8-5 m, combined weith some pairs of symmetrical shafts.

8. Horizontal,Lengthuays slicing marchine: Common knife or superthin knife selected based on customer's demand,high automatiealy, handy operating.

Related Products+More

-

PS-150 Gantry Stacker

Gantry stacker Gantry stacking,motorized or hydraulic lifting & lowering for the upper section.Row-rollers stacking and motorized transverse ejecting for the lower section.

-

CF-150 Cardboard Feeding Machine

Cardboard feeding machine Automatic stacking and collecting of the cardboard. Motorized transverse output,transmitted with broad belt for vertical stacking.

-

Hydraulic mill roll stand

Hydraulic mill roll stand Hydraulic control of the lifting and lowering,clamping and releasing,rightleft movement.

-

Vacuum absorb single facer

Vacuum absorb single facer

Latest News

- corrugated paperboard production line

- Flexo printing die cutting machine linkage line

- SYKM series Fully automatic fflexo printing slot

- YKMseries high speed printing die cutting machine

- Semi automatic printing slotting machine

- Double piece stitching machine

- Double servo stitching machine

- Full automatic folder gluer machine

- semi-automatic folder gluer machine

- Automatic die cutting creasing machine

- Cassette single facer

- Semi-automatic flut laminator (Elevated table)

- Semi-automatic flut laminator

- Other machine

- Hand type die cutting & creasing machine

- Full automatic flut laminator

- Automatic flut lamination (feeder type )

Latest News

- corrugated paperboard production line

- Flexo printing die cutting machine linkage line

- SYKM series Fully automatic fflexo printing slot

- YKMseries high speed printing die cutting machine

- Semi automatic printing slotting machine

- Double piece stitching machine

- Double servo stitching machine

- Full automatic folder gluer machine

- semi-automatic folder gluer machine

- Automatic die cutting creasing machine

- Cassette single facer

- Semi-automatic flut laminator (Elevated table)

- Semi-automatic flut laminator

- Other machine

- Hand type die cutting & creasing machine

- Full automatic flut laminator

- Automatic flut lamination (feeder type )